Related Case Studies

Industry: E-commerce

Technology: Parcel Conveyor System

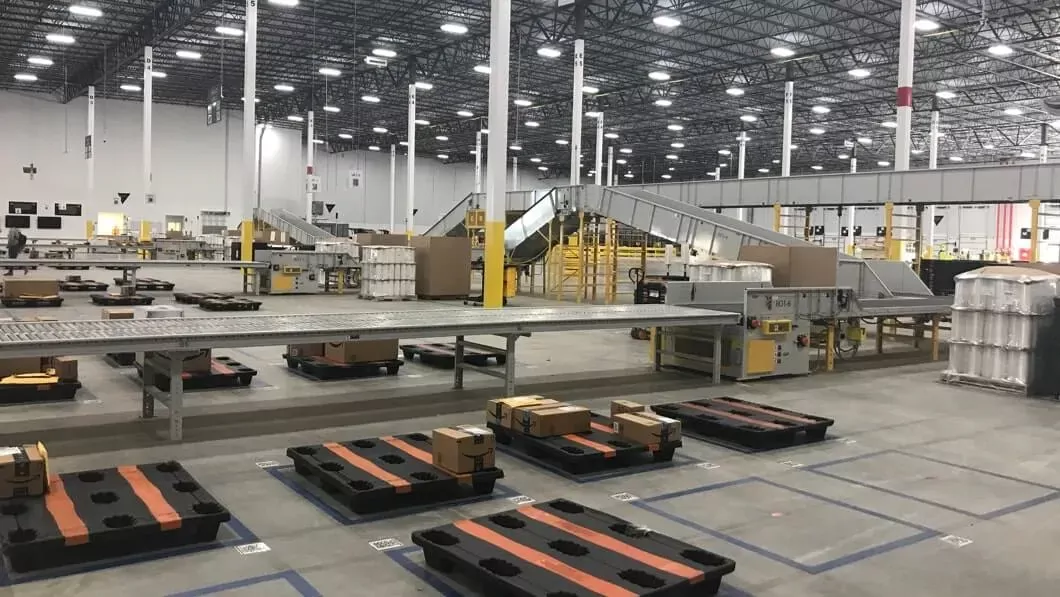

E-commerce Retailer - Mobile, AL

SITUATION:

In order to accommodate their continued growth, this e-commerce retailer commissioned TriFactor to provide a solution to bridge the gap between bulk flow from the local order fulfillment centers to last mile delivery operations. To meet this need, TriFactor designed, procured, installed and commissioned a 3,400 LF, 12,000 parcel per hour bulk sortation system.

The system provides four functional areas: small sorts, unloading, primary sort and a pallet run-out system to feed pallet building. Equipment required to provide the required functionality included VFD controlled bulk parcel conveyor, hydraulic tote dumpers, control panels, air actuated divert plows, sort feed, unloading and associate sort mezzanines, various stainless steel feed and QA chutes and a large, primary sort slide/chute structure.

The result is the retailer now has the ability to sort 12,000 packages per hour in this location, enhancing the quality of its local delivery service, including 1 and 2-day delivery.

TriFactor Provided:

- Needs Analysis Concept Design & Budgeting

- Detailed Design Engineering & Guaranteed Maximum Pricing

- Equipment Selection and Procurement

- Mechanical & Electrical Installation

- Controls & WCS Integration

- Operator and Maintenance Training

Products Utilized:

- 24VDC MDR Conveyor

- Tote Sorter & Put Module

- 3-Level Pick Module (Unit Picks)

- 2-Level Pick Mod (Cigarette/Each Picks)

- Corrugated Waste Conveyor

- Corrugated Waste Compaction System

- High Speed (90 cpm) Cigarette Carton Sorter

- In-Line Tote Banding & Wrapping

- Stretch Wrappers

- Pallet Racking

- In Plant Offices